Innovative electromagnetic clutch for superior comfort

The emDOC electromagnetic dog clutch by HOERBIGER integrates the benefits of a mechanical clutch with the precision of an advanced electromagnetic actuator, enhanced by a position sensor. This intelligent three-in-one solution delivers wear-free actuation while optimizing space, weight, and cost efficiency.

The HOERBIGER emDOC is a highly efficient “On/Off” clutch engineered for secure torque transfer, making it an ideal solution for hybrid and electric drivetrains. It functions as a connect/disconnect mechanism to decouple inactive drivetrain components, such as a secondary axle. Additional applications include multi-gear transmissions to realize different ratio stages as well as parking locks and differential locks, where the emDOC effectively prevents wheel spin. By eliminating the need for external mechanical components, the system reduces part count, conserving installation space, weight, and cost.

Versatile design and flexible application

The HOERBIGER emDOC excels with its scalability and adaptability. Unlike traditional systems that rely on a shift fork and gear reduction for actuation, the emDOC provides a compact, all-in-one solution with integrated actuation. It can be customized for power supplies ranging from 12 to over 48 volts, to meet specific customer requirements.

Smart design and reliable performance

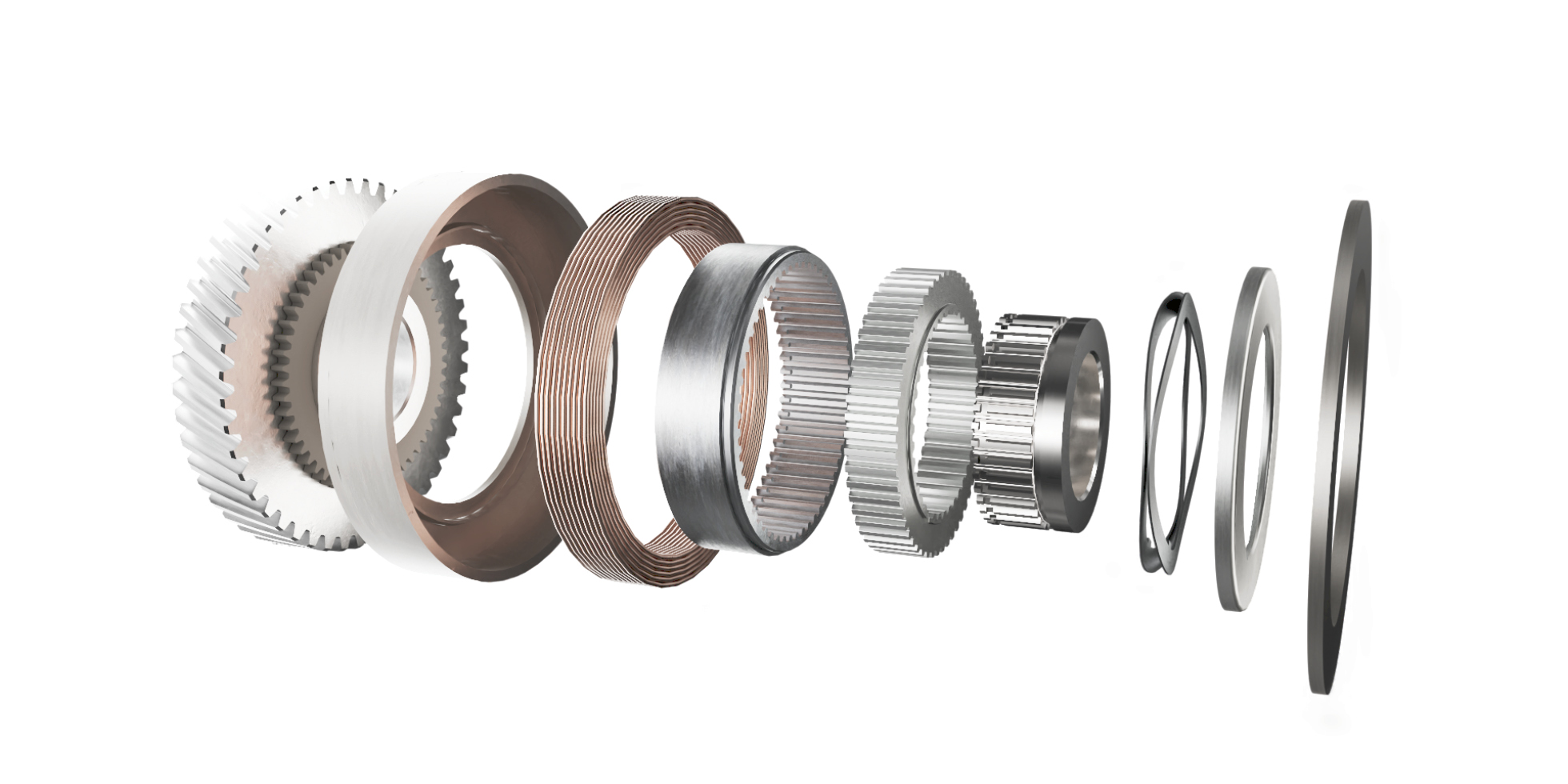

The emDOC system is engineered with an intelligent design for precise and reliable control. It consists of a mechanical clutch system for torque transmission, paired with an electromagnetic actuator and a position sensor. When voltage is applied to the copper coil, it generates a magnetic field that moves the coupling sleeve to the required position. The absence of permanent magnets prevents iron particle adhesion to components, ensuring interference-free and reliable operation.

With the actuator fully integrated into the clutch system, emDOC delivers fast and efficient shifting. Its contactless actuation prevents wear and ensures precise positioning of the coupling sleeve throughout its lifetime. Shifting operations occur directly on the coupling sleeve, guaranteeing exact positioning from the first to the final shift