HPR – Packing Case Repair

Ensure your packing is leak proof

HOERBIGER offers packing reconditioning and parts in multiple ways. Together we choose the solution that best suits your company’s needs. HOERBIGER offers you a choice of different business models: traditional pay-per-job, a formal agreement to improve packing performance, or a comprehensive contract based on jointly defined KPIs such as delivery performance and warranties.

Depending on your needs, HOERBIGER packing reconditioning can cover:

- Reconditioning contract

- Parts availability

- Stocking strategy

- Lifetime warranty

- Upgrade strategies to turn one time capital expenses into operating costs

- Focus on full sealing solution by service and upgrade of piston-rod and piston

This is why Packing Service is vital for your compressor’s lifespan:

- Corrosion, deterioration and surface damage on the packing case cups decreases sealing performance and increases leakage.

- Deposits and dirt in cooling passages hinder heat dissipation and reduce the lifetime of the pressure packing.

- Poor condition of O-rings grooves lead to leakage of gas to cooling water compromising the compressor safety.

- A damaged piston rod surface will worsen the packing sealing performance.

- Root Cause Analysis in case of recurring damages and offered upgrade solutions.

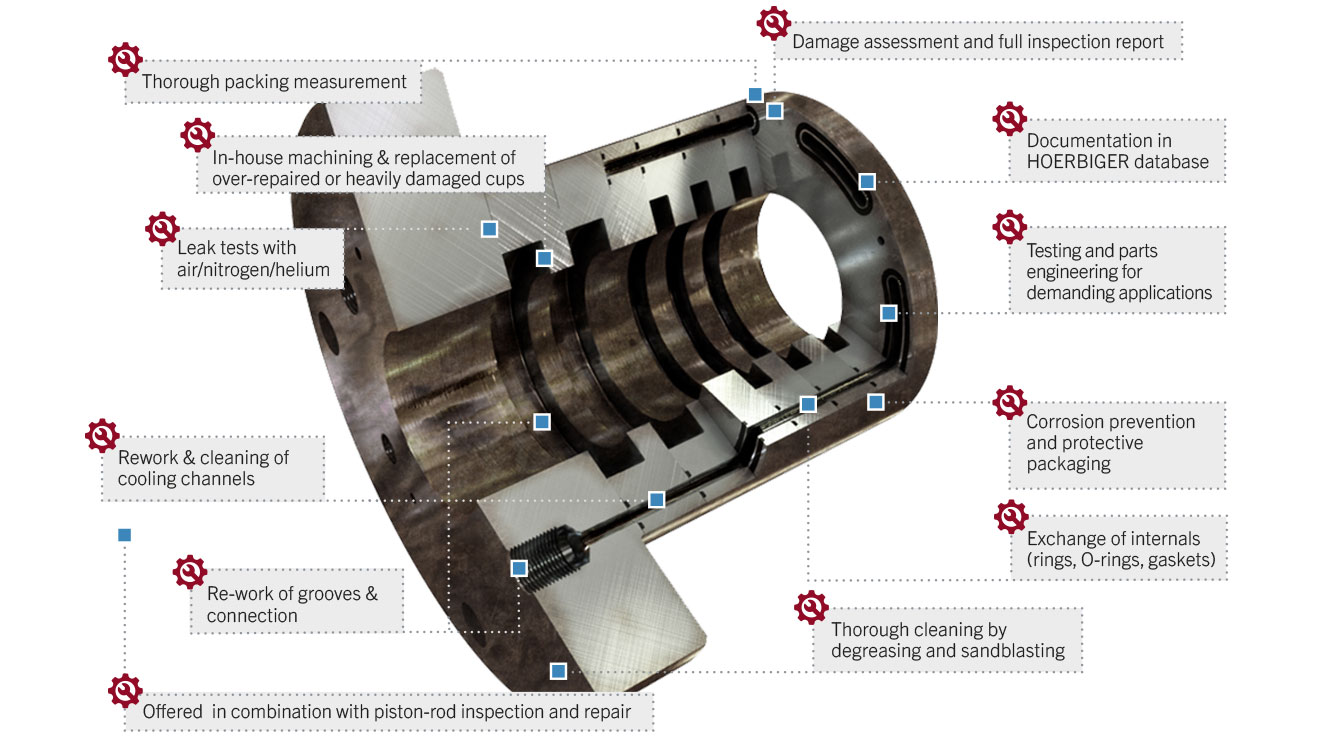

This is what HOERBIGER Packing Reconditioning offers to solve your problems:

- Reconditioning of pressure packings, intermediate packings, oil wiper packings and internals

- Full service, from the replacement of internals to tailored manufacturing of damaged packing cups

- Piston-rod and piston repair as well as upgrade

- Witness testing, including extended leak tests

- Inspection dossier and advanced engineering services

- Expertise and quality from the leading rings & packings manufacturer

- Reconditioned packing cases supplied “as-new” and fully compliant with process needs

Packing Reconditioning makes it possible

The packing case seals the compression chamber and crankcase to prevent emissions of compressed gas and gas leaks into the frame lube oil circuit.

Recent reliability studies have shown that packing cases are one of the most critical components in a reciprocating compressor.

For this reason, proper servicing of packing cases, piston-rod and internals is essential to ensure long-term compressor reliability. All packing cases and piston-rods should be inspected and serviced each time the internals are replaced.

Why HOERBIGER Packing Reconditioning?

- Leakage standards: API 618 and stringent HOERBIGER regulations enforced. Certificate available on request.

- Packing cups and cooling channels leak tested according to API 618.

- One stop shop of pressure, intermediate and wiper packing with piston-rod and piston repair.

- Lapping and flatness check (“light band test“) of all reconditioned cups.

- Advanced machining capabilities (grooves, channels, threads, etc.).

- One-year warranty for all reconditioned packing cases (wear parts excluded). Optional: 2 years warranty.

- Standardized HOERBIGER workshops certified to ISO 9001.

Brochure A4 Format

Brochure Letter Format

How can we help you?

Let us know if you need assistance or have questions – one of our compression representatives will contact you as soon as possible.

Don’t miss out on the latest news!

Sign up below to receive the latest news and updates from HOERBIGER about our compression products and services.